Common Problem

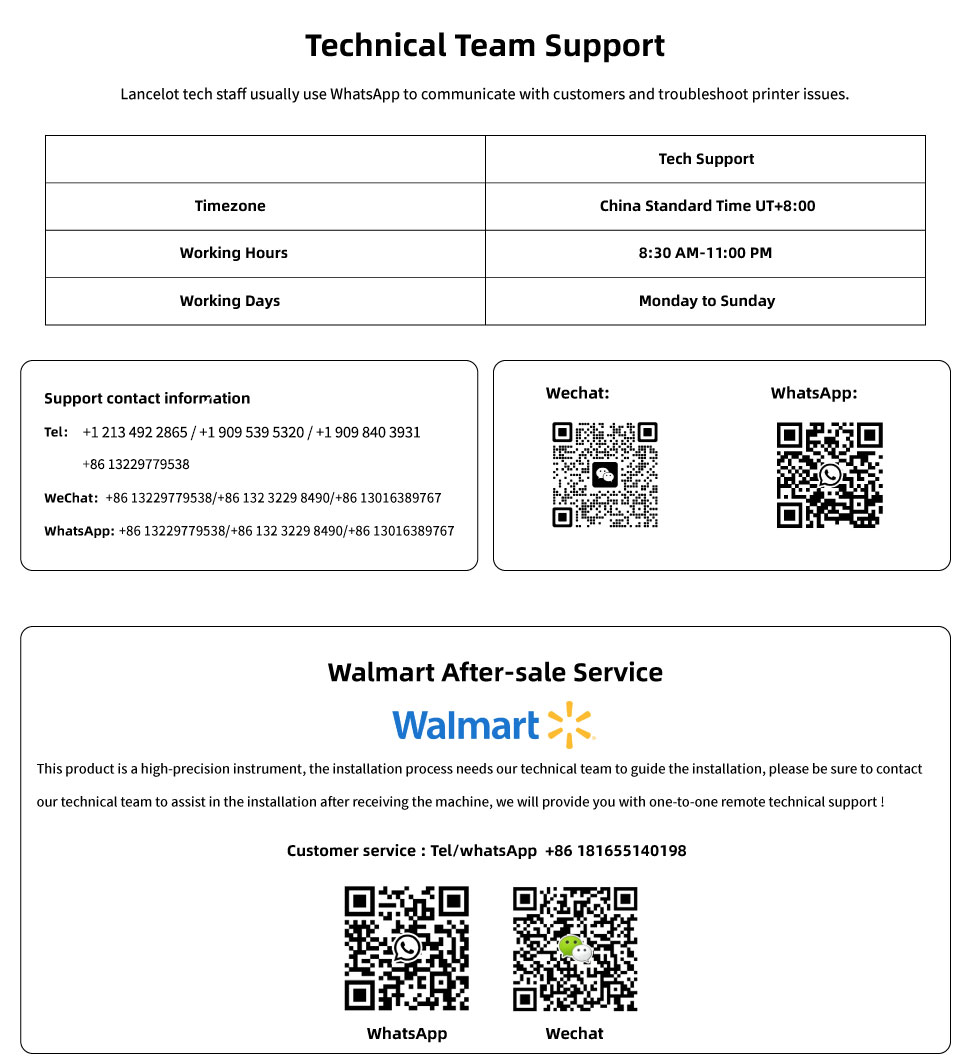

The following reply still cannot solve your problem, please scan the QR code above to contact us!

Q:How to deal with the print head scraping film?

A:If you confirm that the print head scrapes the film, press the emergency stop button, then open the handle, pull the print film flat, and then push the print head back to prevent secondary scratches. Adjust the position of the film and then turn on the printer, and then use the ink filling function and the cleaning function (computer operation) to clean the coating on the surface of the print head and then do a nozzle test until the perfect nozzle test is obtained.👉🏻To know more, please click here!

Q:How to maintain grating strips?

A:Firstly we need to prepare number of fabrics, paper towels, gloves, alcohol and so on. When there is dust on the grating strip. We can wear gloves and gently wipe the grating strip with a non woven fabric or paper towel. If the grating strip is very dirty and difficult to wipe the dirt. We can spray a little alcohol on the non-woven fabric or paper towel and wipe it again.👉🏻To know more, please click here!

Q:How to check the ink cartridges?

A:Before the inspection, we need to prepare ink cartridges, hoses, masking paper, water. First of all, when you receive the cartridge. You should first check whether the cartridge nozzle is broken. Secondly, to test whether the ink cartridge will leak. We need to plug the cartridge nozzle with a hose to prevent water leakage, and fix it with masking paper. Then inject water into it and leave it for a while to see if there will be water leakage at the various ports of the cartridge. If it does not leak, it means that there is no problem with the cartridge.👉🏻To know more, please click here!

Q:How to check the ink damper?

A:Insert the syringe into the ink damper. Push it in gently. If the gas bounces back, it proves there’s no leakage. Press the ink damper, push air in,as long as the ventilation is smooth.👉🏻To know more, please click here!

Q:What should you pay attention to after receiving the film?

A:First of all, what we need to prepare are non-woven gloves and utility knives. Gently scratch open the box to avoid damage to the film. We should not wear any jewelry, belts and other sharp objects on our hands before taking out the film. These factors will cause problems such as scratches and bumps of the film. Please wear non-woven gloves before taking out the film to avoid scratching the film with your nails. Gently stretch the film without touching other items. Be careful when receiving the film. First, fix the printing film bracket on the left side, loosen the printing film bracket on the right side, fix the printing film on the left bracket first and finally fix the printing film on the right bracket, and lock the right bracket.👉🏻To know more, please click here!

Q:How to maintain the machine during a long holiday?

A:First of all, you need to make sure that all the ink dampers are firmly fixed above the print head. Then, please check all the ink pipes. See if there is enough ink in the pipes. If there is air in the ink pipes. Then you need to use the loadink function. Please click on the setting page of printexp software. Then use the loadink function(Please select all heads). Click the loadink button. You can pause it after about 35 seconds. Then, please use the "CLEANING" function of the printer. Wait for the printer to complete the instruction. Then please click the "CHECK" button and do the nozzle test. If you get an incomplete nozzle test pattern. Then you need to do nozzle cleaning and testing again until you get a perfect nozzle test chart. This is a complete pattern of nozzle test. Finally, we need to empty the ink in the waste ink pipeline. You need to get the print head off the ink pad. Then use paper to block the X-axis limit sensor. Then please use the loadink functionin printexp software. Because the sensor is covered by paper,the print head will not go home. At the same time, please inject pure water into the ink pad with a syringe. The pump will pump the water down. This enables us to achieve the purpose of cleaning the pipes. Until the liquid in the waste ink tubes becomes transparent. Then we have completed all the steps. Please take the paper off the sensor and restart the printer. Return the print head directly above the ink pad(This is very important). Shut down according to the normal process, ensure that the nozzle and ink pad can beclosed properly after shutdown. It is best to do nozzle cleaning every 10 to 15 days. You need to turn on the cleaning.👉🏻To know more, please click here!